Build Diary entries for March 2016

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Previous Month | Return to 2016 | Next Month |

| Engineering update 7th March 2016 (1) | |

| 07/03/2016 | |

|

|

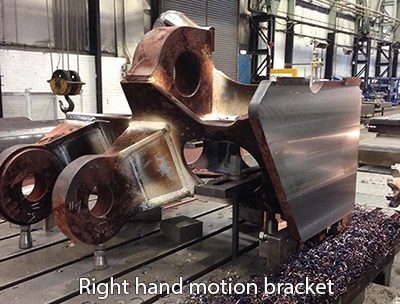

| Another busy week on the engineering front. The sand printed mold for the exhaust steam spider is due to be 'printed' this week. This follows some extensive research that identified a couple of potential hot spots in the mold which would have required remedial work after the part had been cast. The runner and riser system for the mold has now been redesigned accordingly to remove these hot spots, just another example of how 21st century technology is allowing us to test components and manufacturing techniques before a single piece of metal is touched. Photographs and video are going to be taken when the mold is removed from the printing machine marking a first in preservation and a major step forward for one of the last frame assembly components! The left hand motion bracket is being welded together and right hand motion bracket is being machined, both at CTL Seal in Sheffield. Photograph copyright Chris Jones / SSLC Ltd |

|

| Engineering update 7th March 2016 (2) | |

| 07/03/2016 | |

|

|

| RH motion bracket Photograph copyright Chris Jones / SSLC Ltd |

|

| Engineering update 21st March 2016 | |

| 21/03/2016 | |

|

|

| The fabrication of the front firebox support with truck pivot (SL/DE/19871) has begun at CTL Seal (Sheffield). Photos of progress will be posted here as fabrication progresses. Other than that a quiet week. Engineering is full of peaks and troughs as components are ordered then all goes quiet until the fabricating or casting commences followed by machining and testing with plenty of metallurgical and dimensional testing going on in between. | |