Pony Truck Appeal

| If you would like to make a donation to the pony truck appeal, please click the button. Please note that all prices are estimates which may differ from a binding quotation. |

We are grateful to Michael Hughes from the BR Class 8 Steam Locomotive Trust for the reproduction of these photos.

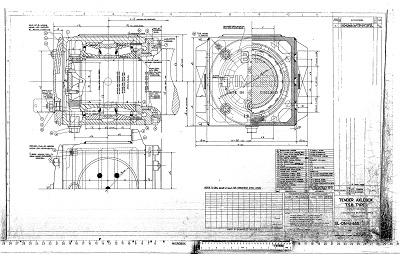

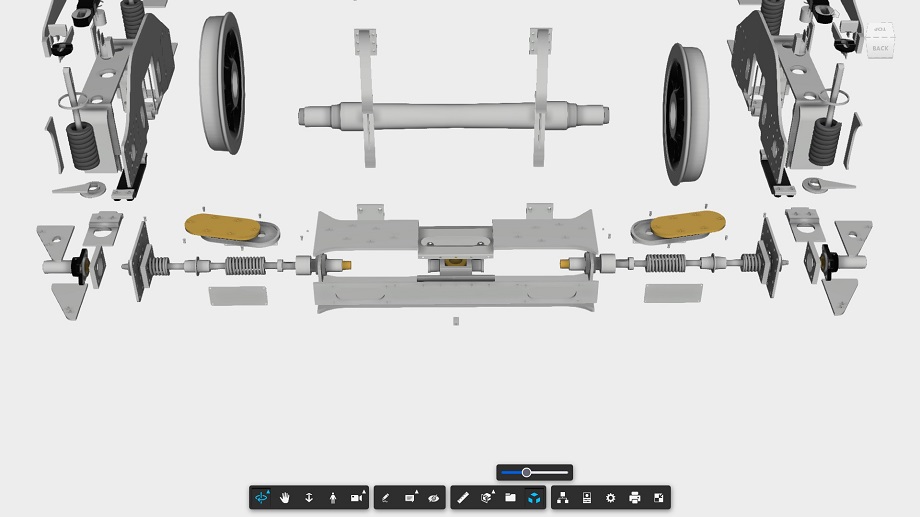

The pony truck is the "2" of a 4-6-2 Pacific locomotive. British Railways called it a pony truck whereas it really is a Delta trailing truck. Delta because the weight of the rear of the locomotive is carried at 3 points.

- A bearing surface around the front pivot which is located below the front of the firebox.

- 2 oval bearing surfaces on the rear beam of the pony truck frame. You can see these on the photograph above.

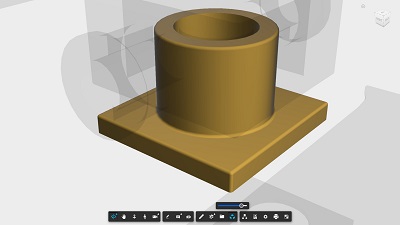

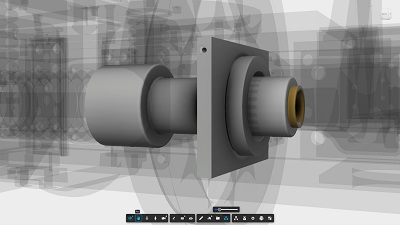

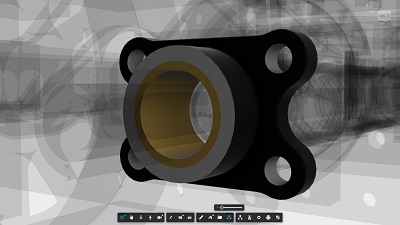

On the oval bearing surfaces are 2 bolster cups which can slide on the oval pads. The bolster cups engage with bolster domes that are bolted to gussets at the rear of the locomotive frames. This system allows the pony truck to pivot around the forward pivot as it negotiates curves in the track.

The Class 6 Clans and the Class 7 Britannias were fitted with an all fabricated pony truck frame with leaf springs. The fabricated frame caused problems as cracks were experienced around the pivot (see Britannia by Philip Atkins Chapter 16). Also the leaf springs gave a hard ride.

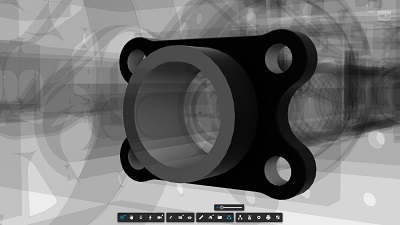

For 71000, Duke of Gloucester, BR came up with a revised design with a cast radius arm (with the front pivot) bolted to a fabricated frame. In addition coil springs were used for the suspension springs instead of leaf springs. This is reported to provide a much better ride. This design was intended for the lot 242 Class 6 build and that is the design we will use for 72010.

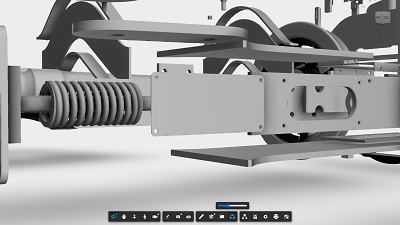

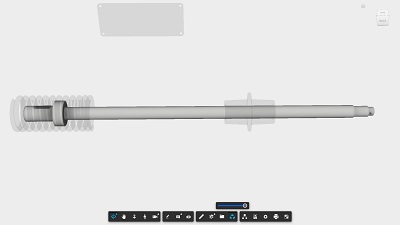

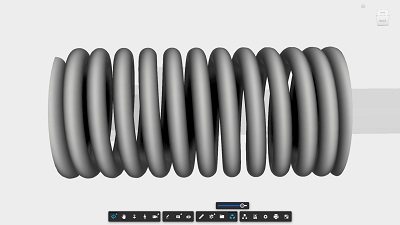

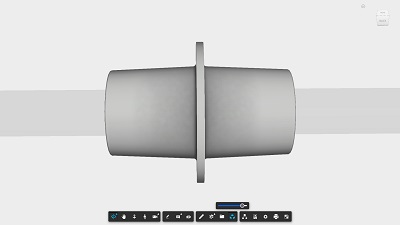

Looking at the front of 71000's delta truck we can see the cast steel triangular radius arm with the load bearing surface around the pivot. This engages with a large pivot pin that locates in a bush on the front firebox stretcher. The radius arm is bolted to the front of the fabricated frame. For the suspension, a spigot locates on the top of the axlebox (via a pad) which transfers the axlebox movement to a horizontal spring beam located between the inner and outer side frames. Guides on the frames restrain the spring beam sideways with manganese steel liners welded to the guides. Spring Links drop down vertically from the ends of the spring beam to the bottom of the coil springs. The tops of the springs are restrained by the frames; therefore as the axlebox moves upwards, the spring beam moves upwards thus compressing the springs.

The axlebox is an outside bearing axlebox (Outside the wheels as opposed to the inside axleboxes fitted to the bogie and coupled wheels). The axlebox contains a pair of Timken taper roller bearings.

Returning to the top photo, we can see another important function of the trailing truck. A square section beam runs across the back of the frames. Inside are 2 pairs of coil springs separated by the shaft of the circular centring pin you can see in the photo. The centring pin is bolted to the bottom of the dragbox which is part of the locomotive's frames. As the trailing truck attempts to pivot, the centring pin will compress one of the pairs of springs. This stabilises the locomotive while running round a curve and also produces a smoother exit.

The bushes of the centring gear are lubricated by the oil box. There is also a pair of grease lubrication pipes to lubricate the centring pin.

Axle and Tyres

| If you would like to make a donation to the pony truck appeal, please click the button. Please note that all prices are estimates which may differ from a binding quotation. |

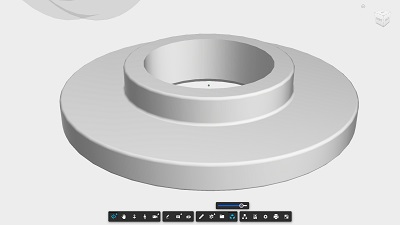

The pony truck wheels were cast by Trefoil Foundry in Sheffield in Spring 2024. Trefoil also organised initial machining.

For phase 1 of the pony truck construction we need to source the long lead items which are the axle and the tyres for the wheels. These components are on a 12 month order delivery. The pony truck wheels are the same as the tender wheels.

Click on the images below for a larger pictures.

Frame Assembly

| If you would like to make a donation to the pony truck appeal, please click the button. Please note that all prices are estimates which may differ from a binding quotation. |

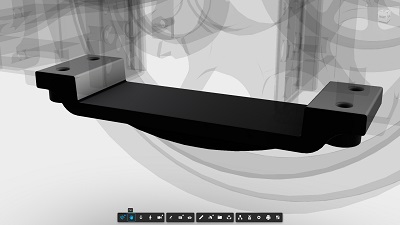

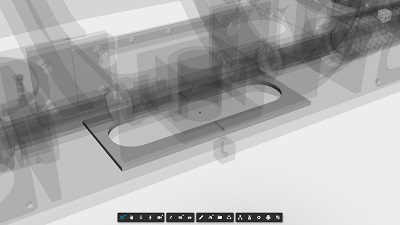

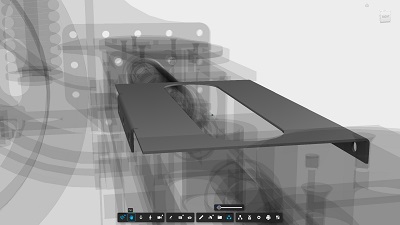

Phase 2 will address the primary components of the pony truck, namely the radial arm and the frame assembly. Like the main frames and the bogie, the frames will be assembled using fitted bolts.

Suspension System

| If you would like to make a donation to the pony truck appeal, please click the button. Please note that all prices are estimates which may differ from a binding quotation. |

Phase 3 addresses the suspension system. Unlike the Mark 1 Clans, 72010 will use the coil springing system used on 71000 - Duke of Gloucester

Centring Gear

| If you would like to make a donation to the pony truck appeal, please click the button. Please note that all prices are estimates which may differ from a binding quotation. |

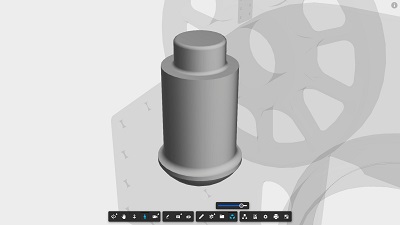

The pony truck centring gear is fitted in the rear beam of the frame. A substantial centring pin is fastenened to the bottom of the dragbox with the pin pointing downwards. This passes through a slot in the frame and engages in a guide fitted within a crosshead. Attached to both sides of the crosshead are spindles which pass through the box frame - the ends are supported by bushes and guides in the end plates of the frames. Each spindle runs through a pair of round section, coil springs to provide the centring force.

Other Items

| If you would like to make a donation to the pony truck appeal, please click the button. Please note that all prices are estimates which may differ from a binding quotation. |

A number of miscellaneous items are need to complete the pony truck.